Range Well Nickel Cobalt Resource in Western Australia.

Nickel Resources

EVM’s upstream integration of the supply chain is based on our Range Well Nickel Cobalt Resource in the tier one mining jurisdiction of Western Australia.

The Range Well Nickel Cobalt Resource is located within 13 contiguous mining leases granted for terms of 20 years and renewable for further terms of 20 years in the world class mining province of Western Australia offering established infrastructure and low sovereign risk. The Range Well Project provides long term optionality with future growth and value creation potential.

This is the largest inventory of Nickel and Cobalt in one location in Australia.

The Range Well Nickel Cobalt Resource comprises 353 million tonnes at 0.65% Nickel, 0.041% Cobalt and 0.18% of Manganese at a cut off grade of 0.50% Nickel.

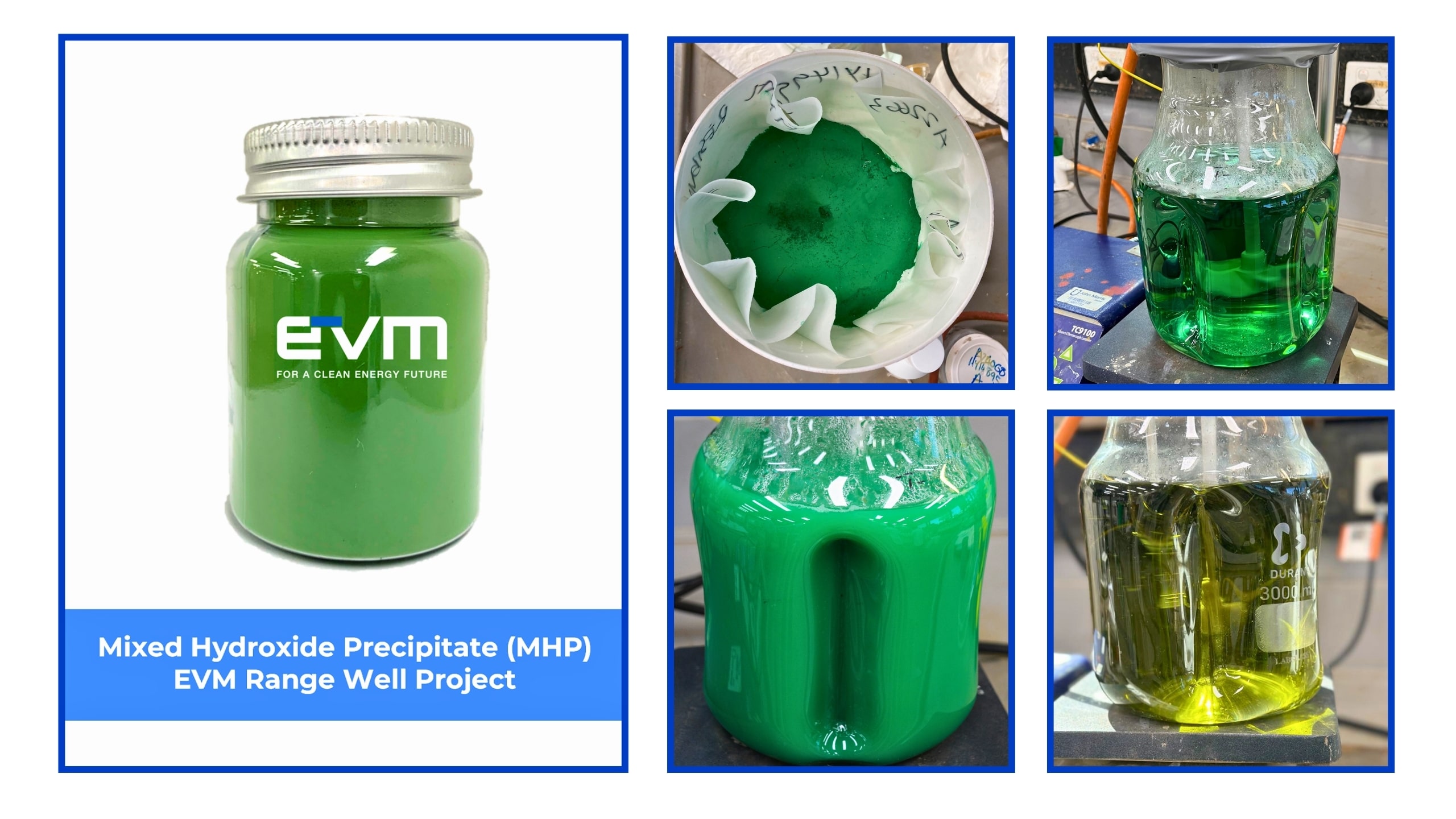

The resource represents over 2.3Mt of Nickel, 145,000t of Cobalt and 640,000t of Manganese. We are working to develop plans to develop a long-life nickel mining and processing operation averaging 170,000 TPA of Mixed Hydroxide Precipitate (MHP) containing 34,000 TPA Nickel, 2,300 TPA Cobalt and 4,300 TPA Manganese.

The Range Well JORC Resource Statement can be found here.

Range Well Nickel Cobalt Resource in Western Australia.

A significant amount of resource definition and geomet and process testwork has been completed to unlock the value of the Range Well resource.

With the support of ALS, a global leader in metallurgical laboratory testing, EVM has completed completed a systematic and substantial metallurgical testwork programme resulting in marked increase in the geometallurgical and metallurgical knowledge of the Range Well deposit.

Key highlights include:

- Beneficiation testwork by wet screening has confirmed that a significant upgrade of ore resource can be achieved, to 1.2% Nickel in HPAL feed.

- A marked increase in geo-metallurgical parameters have been defined, confirming the process selection flowchart and predictive algorithms for determining upgrade and leach performance with high confidence.

- High Pressure Acid Leach (HPAL) tests have demonstrated that slurry and leaching parameters are comparable to or better than similar nickel laterite industry peers, with Ni and Co metal extractions typically exceeding 94%.

- The first Mixed Hydroxide Precipitate (MHP) produced exceptional quality exceeding industry norms, with an average 38.8% Ni, 4.5% Co, and low impurity levels of 0.15% Ca, 1.3% Mg and <0.01% Fe.